| Product Name | KUKA robots for arc welding |

| Product Brand | KUKA |

| Service Area | Automation |

| Youtube | Watch |

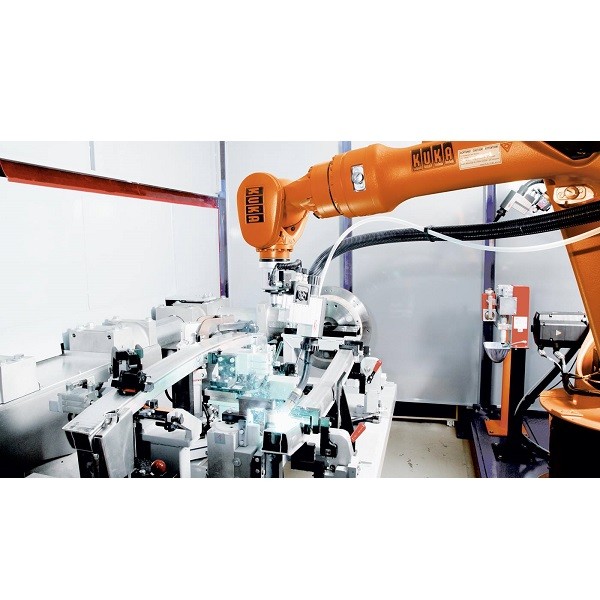

KUKA robots for arc welding

Product Details

- Simplest operator control

The intuitive user interface on the high-resolution touch screen of the KUKA smartPAD in conjunction with the KUKA.ArcTech software enables the fast creation of reliable welding programs. The programmers are supported by simple and clearly structured weld commands. - Quality resulting from extreme accuracy of the weld seam

Due to the outstanding path accuracy of our robots, there is no need for complicated reworking – regardless of whether the welding process involved is MIG/MAG, TIG, plasma or a special welding process. The optional KUKA.TRACC TCP offers the additional possibility of automatically monitoring the torch TCP in the production cycle and updating it if required. This ensures that every seam is welded where it is required. - Utmost productivity

The high axis velocities and the infinitely rotating axis six of our robots ensure particularly low cycle times because the duration of unproductive motions between the weld seams is thus minimized. The excellent repeatability of the stable robot arms ensures accurate positioning at the start of the weld seam without overshoot. KUKA.RoboTeam and ArcTech Advanced enable multiple robots to work on a component simultaneously, thus significantly boosting productivity. - Lowest operating costs

The mechanical systems of our robots are characterized by extremely long maintenance intervals of the gear units and maintenance-free robot cable sets. Together with the energy-efficient KR C4 controller, this ensures minimal operating costs.